TCН HOS (TECHNOLOGY OF CAVITATION TREATMENT)

Task set.

Automation of heavy oil cavitation treatment technology (TCH-technology). This technology is used to reduce the density and viscosity of heavy oil to enable its transportation by pipeline, as well as to convert the cube residue of oil refining to ship fuel standard.

Our Client. His request/challenge.

CPP TESTING SAS is a refinery in Chia (Cundinamarca region). Specializes in ancillary activities for the extraction of minerals, including oil. Applied for the installation of a cavitation unit in order to process oil and fuel oil, obtain more light oil products and, as a result, capture of economic returns while improving the quality of the feedstock.

Problem/tasks of the Client that he faced before he contacted us

Search for a cost-effective and efficient technology for the additional processing of oil and fuel oil at production facilities.

Tasks set by the client:

- Improving the quality of the original oil to increase the yield of light oil products after processing.

- Improving the quality of the fuel oil (decrease in pour point and increase in flash point).

- To ensure the production of processed oil at a level of at least 1000 barrels per day.

Solutions that we offer to the client:

TCH specialists together with the Automation Spirit Alliance has developed a technology for cavitation treatment of oil and oil products. As a result of cooperation, first an experimental, and then an industrial model of the unit was obtained.

“Method of processing hydrocarbon raw materials” means hydro-dynamic processing of raw materials with active cavitation under strict technological conditions. The capacity of one cavitator is 1400 bar/day.

How it works?

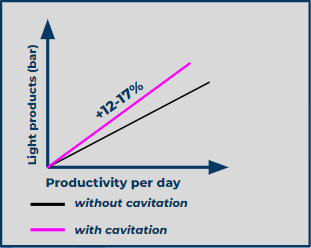

Results achieved after installing the cavitator: light products

Increase in the yield of light products during the processing of modified oil by 12-17%.

Results achieved after installing the cavitator: fuel oil

Initial data:

Fuel oil does not meet generally accepted standards. Requires modification with diluents. Diesel is used as a diluent in the amount of 30%, which increases the price of the finished product.

When using cheaper naphtha, the flash point drops to critical values. Need another solution

An effective solution from TCH and ASA:

15% of diesel + 2% of naphtha + cavitation process gives the result required by the client:

- reduce the pour point from 33 to 21 °C

- flash point not lower than 60 °C

The rest of the indicators are brought to the specified standard.

About the technology and lab tests results

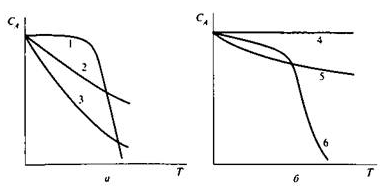

Effect of cavitation on oil:

Under the influence of cavitation treatment on oil according to the TSH technology, an irreversible destruction of the structural lattice formed by the molecules of paraffins, resins and asphaltenes occurs. In this case, there is a decrease in the amount and a change in the chemical composition of the oil residue, namely, the content of asphaltenes increases and the content of paraffin-naphthenic hydrocarbons decreases.

Unlike traditional oil thermal treatment, which leads to the formation of coke, cavitation is carried out in mild temperature conditions using other types of energy.

The main goal is to break the least strong chemical bonds in the oil components and achieve the correct interaction of the formed radicals with the donor component (hydrogen).

The unique oil cavitation treatment method, developed by the TCH engineers together with Automation Spirit Alliance specialists, has passed all the necessary tests and proved its effectiveness at various production volumes.

If it is necessary to increase production volumes over 1400 bar per day, it is possible to install 2 or more cavitators. The method is patented in many countries of America, Europe and Asia.

If you are interested in our technology, please contact us using the form below.