JAKUSZ (POLAND)

The set task

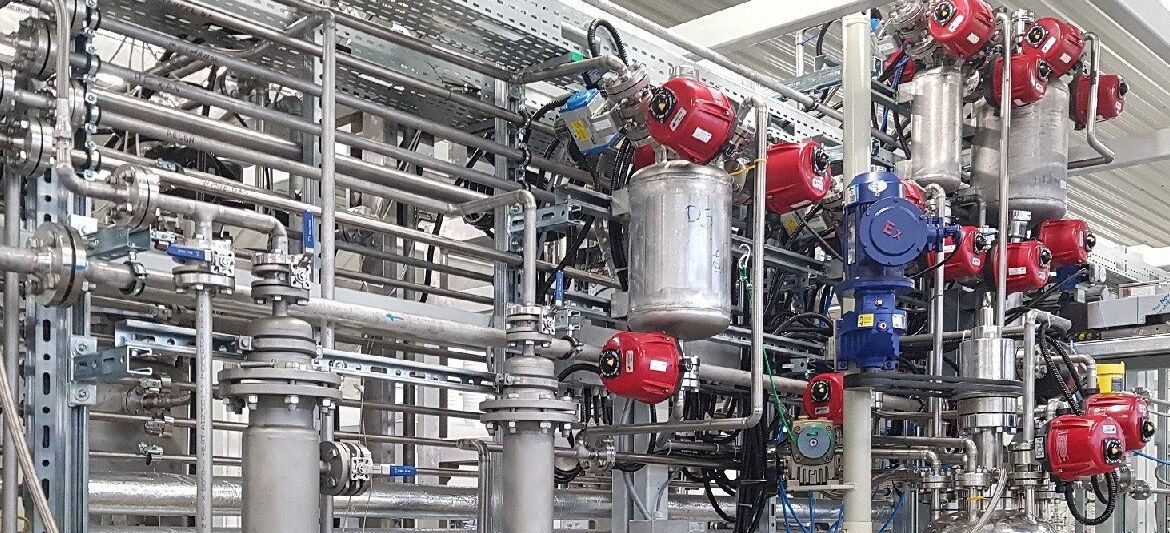

Development of an automated process control system (PCS) for a synthesis and modification of butadiene rubbers with installation control from a sensor control panel installed “locally”. ACS has to be developed with consideration of requirements for fire and explosion safety (Ex/ATEX)

The proposed solution

PCS is implemented on the basis of SCADA Simplicity by General Electric and Simatic S7-1500 controllers with ET200SP input/output modules by Siemens. To provide control of electric drives with variable speed there were used Altivar frequency drives by Schneider Electric. Man-machine interface has been implemented on the basis of panel computer SIMATIC Comfort Panel Outdoor by Siemens company.

Work performed and result achieved

The APCS was delivered to the customer, Jakusz, in 2019. At the customer’s site in Szymbark, Pomeranian Voivodeship, Poland, the installation and commissioning of the equipment was carried out, together with customer representatives carried out synthesis of test batches of butadiene rubber.