PLC / HMI / SCADA DEVELOPMENT

Our position in software development is the openness of the program code. We provide the customer with all projects and program codes with their description. If necessary, we set up password protection for reading and changing the program.

We provide software development services for the following types of industrial control systems: PLC / HMI / SCADA

PLC software development

This type of software is developed in a development environment for a particular type of PLC in the IEC 61131 (European standard EN 61131) family languages. Depending on the automation platform different development environments are used such as Simatic Step7, TIA Portal, Unity Pro, CoDeSys, Cimplicity Machine Edition, CScape etc.

The PLC software performs the following functions:

Interrogation of discrete and analog inputs at the local PLC garbage can, expansion garbage can, and remote stations;

Primary conversion of input signals (debounce and validation, analog signal conversion, warning and alarm limit evaluation;

Execution of fast subroutines in accordance with the algorithms of emergency protections;

Verification of interlocks;

Execution of basic control algorithms, including PID controllers;

Providing information to the upper level, receiving commands from the upper level

Issuing control signals to discrete and analog outputs of local PLC baskets, expansion baskets, and remote I/O stations;

Communication exchange over digital interfaces (ProfibusDP, ModbusRTU, ModbusTCP, etc.).

We own the necessary licenses for the instrumental software, so the cost of development includes only labor intensity and the author’s developments on the application software. However, on customer’s request we can supply instrumental software with all necessary licenses, allowing the customer to make changes in the application program independently.

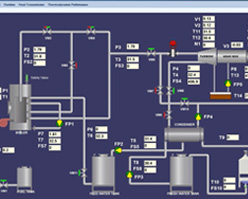

SCADA software development

SCADA-system software is developed using SCADA-package of one of the well-known manufacturers. Depending on the automation platform different packages are used such as InTouch, WinCC, Cimplicity Plant Edition, Vijeo Citect. In fact, for any automation platform any SCADA-package that performs information exchange with PLC through OPC driver can be used.

SCADA-system software performs the following functions:

Provides the operator with an interface to operate the SCADA system in the form of process mnemonic diagrams, control panels and information windows. Information is provided in visual-graphic, numeric, tabular and graphical forms;

Exchange of information with the PLC;

Archiving information and event logs, and viewing archives;

Forming reporting forms and documentation;

User rights management.

SCADA-system software operates under Windows operating system. Runtime license is required for operation, which is purchased separately for each SCADA-system workstation. The cost of the license depends on the number of points (tags, I/O channels) in the system, the need to purchase specific drivers, the need for additional services such as full-function archiving, the provision of WEB-interface, etc.

HMI software development

Operator panel software is designed to provide human-machine interface on industrial liquid-crystal panels, embedded in operator stations. Depending on the type of operator panel, different software development products are used, such as WinCC Flexible, Vijeo Designer, etc.

Runtime license and operating system are included in the cost of the operator panel itself, and some development packages are free or conditionally free. Often, the software includes services such as WEB-interface, major industrial protocols for digital interfaces, OPC server, and others.

Functions of operator panels software are similar to software functions of SCADA-systems, with the difference that they provide more simplified capabilities and, as a rule, panels are not used for archiving and report generation.

All software for the designed APCS is tested by using the means of mathematical modeling on the test bench, which presents several types of PLCs and operator panels. This testing allows you to eliminate all the errors and adjust the system before installing the software on the Customer’s equipment.